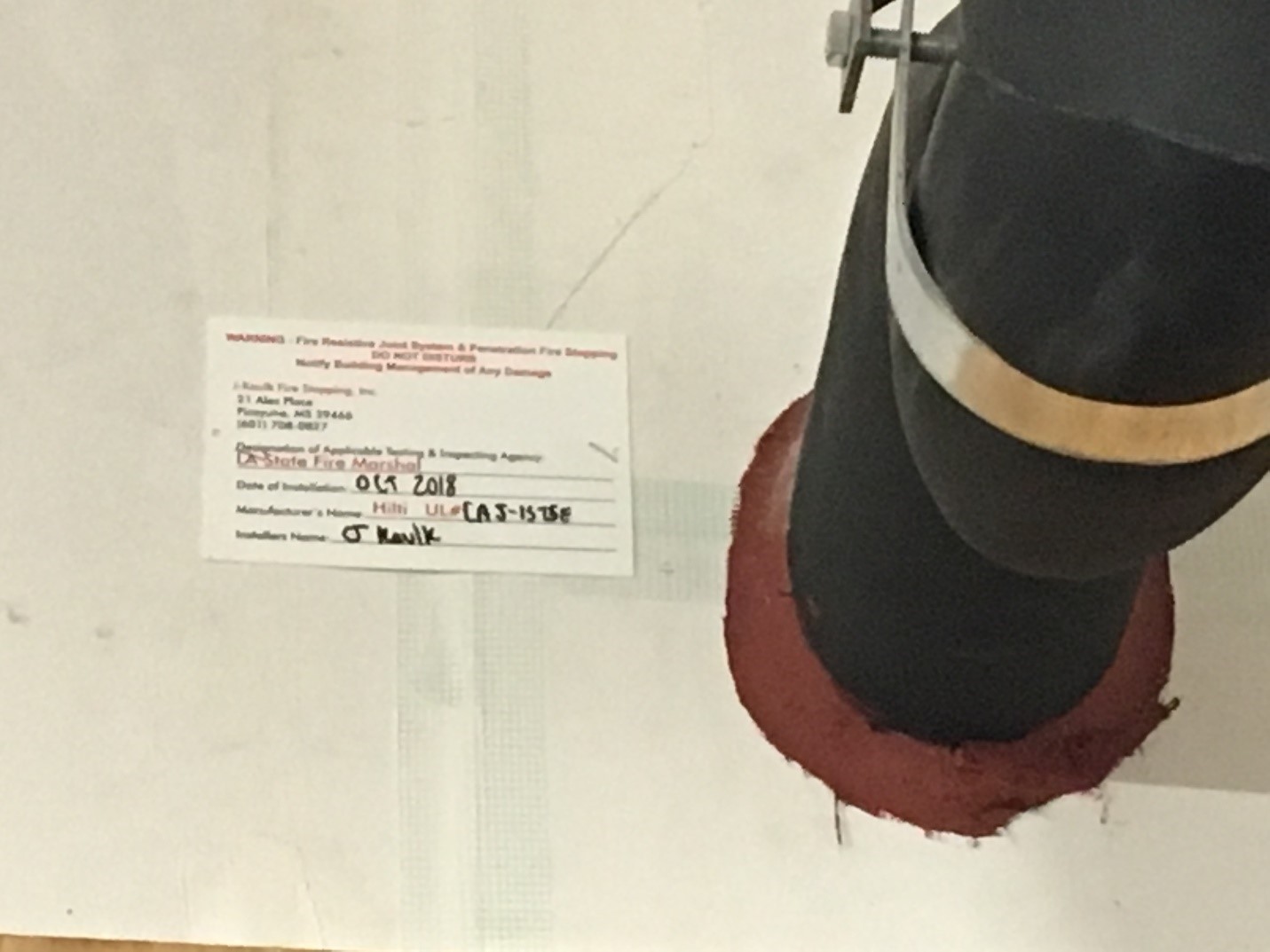

The building code requires that fire rated walls be labeled and some project specifications require the firestop installations to be labeled. If your team does not know the naming system used by UL; they are going to struggle to find the proper details to put on the label. Keep in mind, they are supposed to be using the firestop submittal to direct their installation. If they can get the label right, do you think they even know the specifics of the firestop system? All it takes is a lawyer who knows this nomenclature and this firestop installed has some serious litigation to deal with. My challenge for you…do you know what is wrong with the UL detail listed on the label?

NOTE: We need to blur out sections of this photo that identify the company or project

This one might seem like a silly thing to “pick on”, but it speaks volumes to a firestop installer or an inspector. In this case the guy could not have gotten it any more wrong. The naming system has two parts. The ABC’s followed by the 123s. the ABC’s tells you about the rated assembly. The field condition is a gypsum wall. This should be WL. They listed CAJ, which is for concrete floors or walls. The next part they screwed up is the 123 section. 1000 series details are for metal pipes. This is an insulated pipe so that should be the 5000 series details. If you deal in firestop, you NEED to know this.

If you want to learn this I have great news. We have a FREE CLASS for you.

This is a 1-hour G500 floor/ceiling assembly and a 2”PVC pipe through the ceiling assembly. Submitted detail F-E-2013

Have a look at the firestop detail as well as the installation instruction for the firestop sealant. How many issues can you find with this installation?

Firestop detail : https://multimedia.3m.com/mws/media/197681O/system-no-f-e-2013.pdf

install instructions :https://multimedia.3m.com/mws/media/207329O/3m-fire-barrier-sealant-ic-15wb-technical-data-sheet.pdf

Problem 1: The installation instructions say you have to install the firestop sealant to a cleaned to allow for proper adhesion of the firestop

Problem 2: The installation instruction call for the firestop sealant to be tooled within 5 min.

Problem 3: Sealant depth is to be 5/8” in the full annular space, but because this drywall section is broken it’s not possible for the installer to get this right.

If you have a project with this sort of floor ceiling assembly, reach out and I will give you a few pointers to help your team build better.